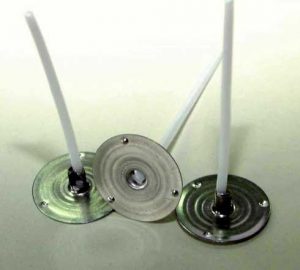

With our wick-wick sustainer mounting machine, the model EDP, waxed wicks (see wick waxing plant DWA) are cut to the set measure, a metal wick sustainer is pre-sorted, brought into the correct position, so that the wick can be inserted and thus is sealed and crimped.

The wicks produced this way are suitable for manual insertion in candle blanks with a pre-drilled or pre-formed wick hole or in containers for subsequent filling with wax. For example, rustic candles, cemetery candles or lights can be provided manually with a prefabricated wick or can be glued into a container for glass candles, fragranced candles or grave lights.

The wick length can be set to any length, as required, by using the operating panel and the corresponding control unit. Different wick sustainers can also be processed. The machine is equipped with an output counter and can be optionally equipped with the patented fully-automated wick fault elimination.

- Capacity: Up to 12,000 wick assemblies/hour (depending on the desired wick length)

Product data:

- Wick diameter up to 3 mm

- Wick length infinitely variable

- Wick sustainer up to Ø 20 mm (optional up to Ø 48 mm round, 60 mm rectangular)

If the dimensions listed here do not correspond to your requirements, we also have a solution for your special application. Simply contact us.

We offer diverse wick insert and wick placement machines for fully-automated inserting of the wick. These can be found under “Wicking”.