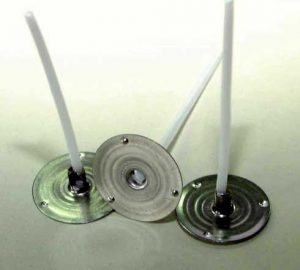

Wicking is a complex procedure which partially has to take place within milliseconds. The variety of containers as well as the wick / wick sustainer plate / glue combination makes this a very multi-facetted process. Here, too, the machine can be configured individually depending on the application. Even the crimping of the wick itself in the wick sustainer plate can take place in diverse forms.

Herrhammer offers a wide selection of powerful and flexible wicking systems and wick sustainer mounting machines for all products. A fully-automated wicking machine can thus easily replace 4-5 persons and relieve them from monotonous work.

Regardless of whether tealight, cemetery light, glass candles, fragranced candles or other container candles, we do more than just putting the wick into a container. It is also possible to wick pillar candles, pressed tealights or votives. Irrespective of whether an individual wick or multiple wicks are required, we have the wicking machine which is perfectly suitable for each case.

Naturally the focus lies on operator friendliness as well as reliability. Easy product change, highest availability and effectiveness turn our wicking machines into the key components for effective candle manufacturing.