There are different procedures for manufacturing powder from wax for pressing. These are selected depending on the installation location and material requirements for the end product.

As an alternative to our powder spraying drums, a powder spraying chamber is available which represents a further procedure for powder manufacturing. The advantages of the powder spray chamber are:

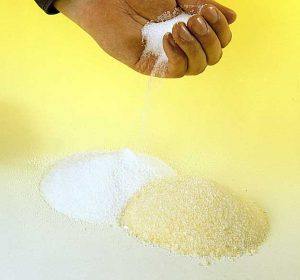

- Highly free-flowing powder since round grains

- Smaller grain sizes

- Energy savings through use of cool outside air possible

- Stainless steel version; therefore processing of stearic acids

and other aggressive materials possible

The spraying tower is particularly popular in colder areas such as Scandinavia since the cool ambient air can be used there to cool the powder. The cost-free cooling medium thus reduces the costs to a minimum.

Our spray towers can manufacture up to 1,000 kg of powder per hour. Its round grains means that it is characterized by its high free-flowing properties.

Options

- Heat exchangers for the optimization of the paraffin wax temperature and machine performance

- Powder silo with conveyor system

- Vacuum conveyor

- Water recooling devices