75 YEARS

TECHNOLOGY FOR CANDLES

Alfred Herrhammer founded his company as a repair shop for machine tools. After being approached by a local candle maker to repair a machine damaged during World War II, Mr. Herrhammer offered to build a new machine. The customer liked the idea, so he developed his first “candle machine”. This machine milled the head on a candle. Its easy operation, simple format change as well as output, fast became known in the industry. Customers asked for machines to fulfil other candle making tasks, soon a machine program was developed. Continuing demand of Herrhammer machines, required constant expansion throughout the years made Herrhammer a worldwide player in the candle industry.

We are grateful to be able to celebrate this great anniversary and thank all our highly valued customers and business partners.

Your Advantages:

- Decades of know-how

- Experience for all kinds of candles

- Strong partner in the industry

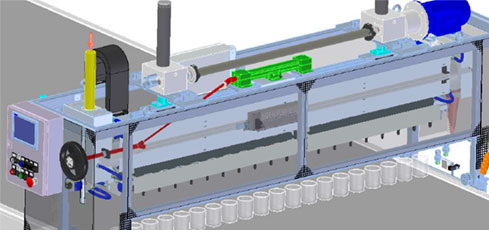

CONTINUOUS WICK INSERTING MACHINE

Your Advantages

- Output increase

- Noise reduction

- Wear reduction

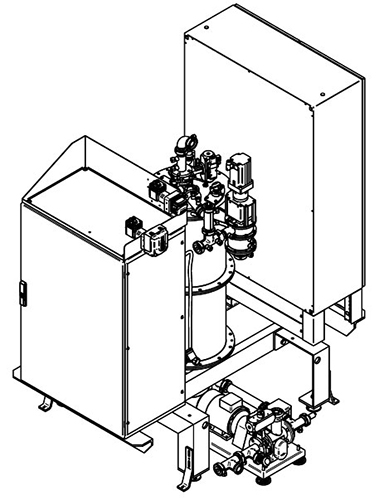

NEW SCRAPER COOLER GENERATION

• Flexibility in terms of material types and percentage

The result was a completely new scraper design with integrated water temperature regulation.

We keep a testing unit at our facility and offer trials with customer material. You are welcome to try.

Your Advantages

- Flexible in choice of material

- Higher output

- Influence of material characteristics

NEW FILLER GENERATION

This exceptional filler can fill liquid as well as slurry material. It provides higher filling speed and at the same time more accuracy than conventional gravity and piston style fillers.

The design was made also considering waste reduction and fast cleaning capabilities. As a result, we achieved a waste reduction of up to 95%.

No matter if decorative candles, filled moulds or grave lights, it makes the best filler for all container filling requirements. The patent of this great technology is pending.

Your Advantages

- More output

- Less waste

- Faster changeover

Do you have questions regarding this or any other topic? Please contact us at:

Tel.: +49 9331 907-0

Fax: +49 9331 907-11

e-mail: mail{at}herrhammer.de

> Download Herrhammer newsletter as digital e-paper